Sechinhu chinoshandiswa zvakanyanya pombi, ductile iron pombi inoita basa rakakosha muminda yakawanda. Nekudaro, ultrasonic ruzha velocity kuyerwa inopa indasitiri-inozivikanwa uye yakavimbika nzira yekuona kuvimbika kwezvinhu zvezvikamu.

1. Ductile iron pipe uye kushandiswa kwayo

DINSENductile iron pipei pombi yakagadzirwa ne ductile iron ne centrifugal casting process. Iyo ine mabhenefiti ekusimba kwepamusoro, kuomarara kwepamusoro, kushorwa kwecorrosion, kupikisa kwakanyanya, nezvimwewo, uye inoshandiswa zvakanyanya mukupihwa kwemvura yemumaguta, kudhiraivha, kutapurirana gasi nemamwe minda.

Mumadhorobha ekupa mvura masisitimu, pombi dzesimbi dze ductile dzinogona kumira kudzvanywa kwemvura yakakwira kuti ive nechokwadi chekufambisa kwakachengeteka kwezviwanikwa zvemvura. Kuramba kwayo kwakanaka kwekuora kunoitawo kuti isanyanya kukanganiswa nekusvibiswa mumvura panguva yekushandiswa kwenguva refu, kuwedzera hupenyu hwebasa repombi. Muchirongwa chemvura, kusimba kwepamusoro uye kusimba kwepombi dzesimbi dze ductile dzinogona kumira nekutsvaira kwetsvina uye kuita kwemasimba ekunze kuve nechokwadi chekushanda kwakagadzikana kweiyo drainage system. Mukuwedzera, ductile iron pipes inoitawo basa rinokosha muminda yakadai sekufambisa gasi. Kuiswa chisimbiso kwavo kwakanaka kunogona kudzivirira gasi kubuda uye kuchengetedza hupenyu hwevanhu nezvinhu.

2. Nzira uye zvikonzero zvekuona spheroidization rate ye ductile iron pipes

Nzira dzekuona

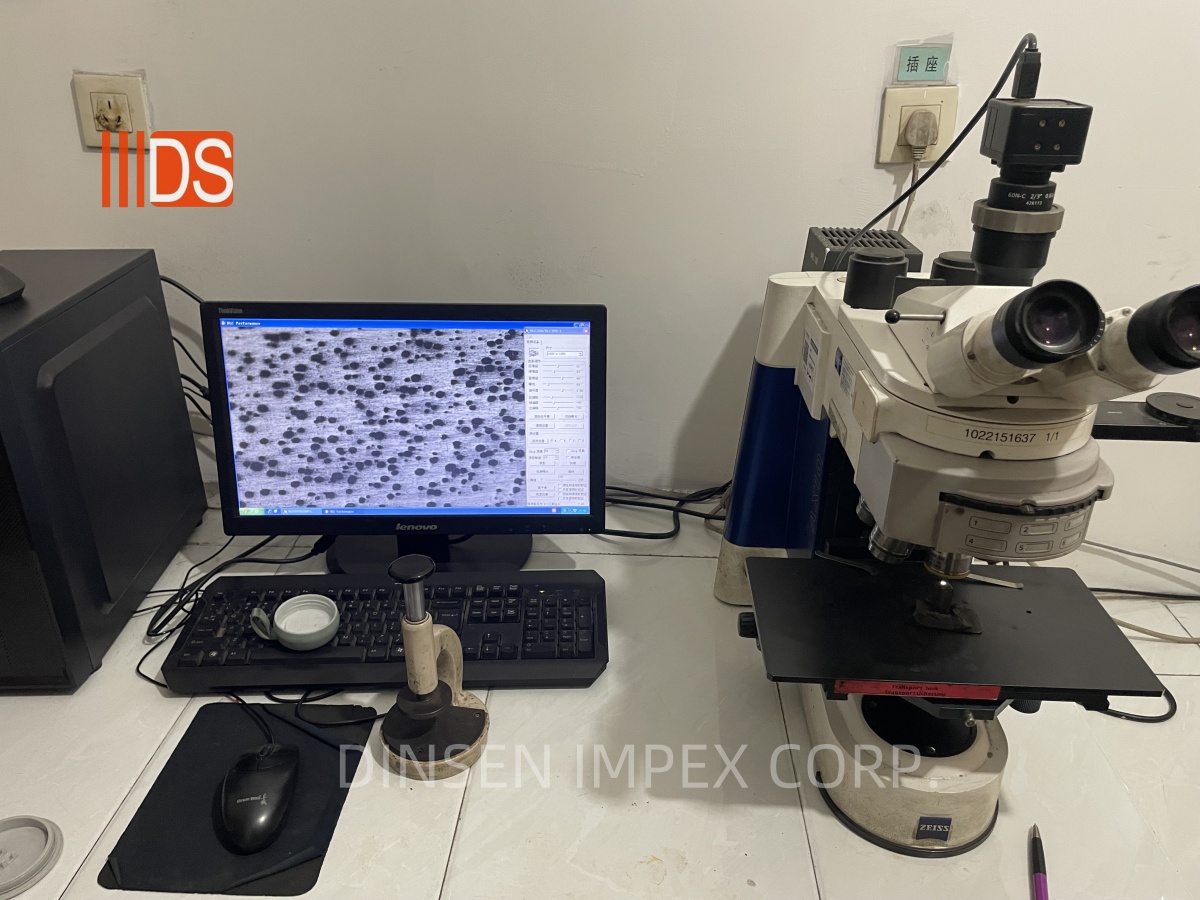

Metallographic yekuongorora nzira: Iyi inzira inowanzoshandiswa yekuona iyo spheroidization rate. Nekugadzirira metallographic samples dze ductile iron mapaipi, iyo morphology uye kugovera graphite inocherechedzwa pasi pemaikorosikopu kuona spheroidization rate. Matanho chaiwo anosanganisira sampling, inlaying, grinding, polishing, corrosion and observation. Iyo metallographic yekuongorora nzira inogona kuona intuitively iyo spheroidization dhigirii regraphite, asi kushanda kwacho kwakaoma uye kunoda hunyanzvi michina uye matekiniki.

Ultrasonic yekuona nzira: Iyo spheroidization mwero inoonekwa nekushandisa kuparadzira maitiro eiyo ultrasonic mafungu mu ductile iron mapaipi. Iyo yekuparadzira kumhanya uye attenuation yemafungu e ultrasonic mu ductile iron ine akasiyana spheroidization madhigirii akasiyana. Nekuyera ma paramita emafungu e ultrasonic, iyo spheroidization rate inogona kuderedzwa. Iyi nzira ine zvakanakira kukurumidza, kusaparadza uye kwakaringana, asi inoda nyanzvi yekuongorora ultrasonic michina uye software.

Thermal yekuongorora nzira: Iyo spheroidization mwero inotarwa nekuyera shanduko yekupisa ye ductile iron mapaipi panguva yekutonhora. Ductile iron ine yakanaka spheroidization ichange iine chaiyo yekudziya shanduko macurves panguva yekutonhora. Nekuongorora aya macurves, chiyero che spheroidization chinogona kutsanangurwa. Kuongorora kwekushisa kune zvakanakira zvekushanda kuri nyore uye kukurumidza kukurumidza, asi kurongeka kwayo kwakaderera.

Chikonzero chekuedza

Ita shuwa chigadzirwa chemhando: Spheroidization mwero ndechimwe chezviratidzo zvakakosha zve ductile iron pombi mhando. Iyo yakakwirira iyo spheroidization rate, zviri nani kusimba, kusimba uye kushora kuramba kwepombi. Nekuyedza iyo spheroidization mwero, inogona kuve nechokwadi chekuti mhando ye ductile iron pombi inosangana nezvinodiwa zvakajairwa uye inopa vashandisi zvigadzirwa zvakavimbika.

Gadzirisa maitiro ekugadzira: Mhedzisiro yebvunzo ye spheroidization rate inogona kudzoserwa kune vanogadzira kuti vavabatsire kukwirisa maitiro ekugadzira. Semuenzaniso, kana spheroidization rate yakaderera, chiyero che spheroidizer chakawedzerwa, kukanda tembiricha uye mamwe ma parameter anogona kugadziriswa kuti awedzere spheroidization rate, nekudaro kuvandudza chigadzirwa chemhando.

Sangana nezvinodiwa nevatengi: Mune mamwe minda yakakosha, senge yakakwira-kumanikidza gasi kutapurirana, spheroidization mwero we ductile iron mapaipi akakwira zvakanyanya. Nekuyedza spheroidization rate, zvinokwanisika kusangana nezvinodiwa nevatengi uye kugadzirisa kukwikwidza kwemusika kwezvigadzirwa.

3. DINSEN laboratory inopa ductile iron pipe spheroidization rate yekuongorora kune vatengi veRussia

Vhiki rapfuura, DINSEN marabhoritari yakapa ductile iron pombi spheroidization rate yekuyedza masevhisi kune vatengi veRussia. Mushure mekugamuchira komisheni yemutengi, takakurumidza kuronga timu yehunyanzvi yehunyanzvi uye takagadzira hurongwa hwekuyedza hwakadzama.

Kutanga, isu takashandisa musanganiswa we metallographic ongororo uye ultrasonic bvunzo kuita bvunzo yakazara yeiyo ductile iron pombi. Metallographic analysis results yakaratidza kuti graphite mu ductile iron pipe yaiva yakanaka morphology uye high spheroidization rate. Iwo ma ultrasonic test results aienderanawo ne metallographic analysis results, zvichienderera mberi nekuonesa huchokwadi hwemhinduro dzebvunzo.

Chechipiri, takapa mutengi gwaro rekuyedza rakadzama, kusanganisira nzira yekuyedza, mhinduro dzebvunzo, mhedzisiro yekuongorora, nezvimwewo. Mutengi akagutsikana zvakanyanya nebasa redu rekuyedza uye akati acharamba achishandira pamwe nesu.

Kuburikidza neiri sevhisi yekuyedza, isu hatina kungopa vatengi vekuRussia zvemhando yepamusoro bvunzo mhinduro, asi zvakare takaunganidza ruzivo rwakapfuma mu spheroidization rate yekuyedza mapaipi e ductile iron. Ticharamba tichishanda nesimba kuti tipe vatengi vane hunyanzvi uye hunoshanda hwekuyedza masevhisi uye kubatsira mukusimudzira indasitiri ye ductile iron pombi.

Muchidimbu, iyo spheroidization rate bvunzo ye ductile iron mapaipi inzira yakakosha yekuve nechokwadi chemhando yechigadzirwa, kukwidziridza maitiro ekugadzira, uye kusangana nezvinodiwa nevatengi.DINSENRabhoritari icharamba ichipa vatengi mabasa ehunyanzvi ekuyedza uye kubatsira mukusimudzira indasitiri ye ductile iron pombi.

Nguva yekutumira: Zvita-17-2024